Industrial Sludge: The Hidden Environmental Challenge and Sustainable Solutions (2025 Guide)

By BKThemes

Understanding Industrial Sludge and Its Environmental Impact

What Is Industrial Sludge?

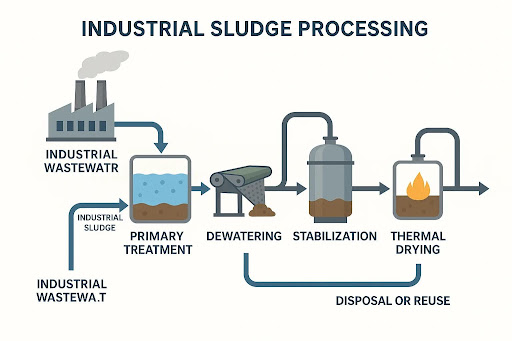

Industrial sludge is the semi-solid waste generated during industrial wastewater treatment processes. It’s composed of water, organic matter, heavy metals, and chemical compounds—byproducts from manufacturing, textile, chemical, metal, and pharmaceutical operations. As industries treat their wastewater before discharge, contaminants settle out as sludge. While the water can often be purified and reused, the sludge itself remains a major environmental concern due to its potentially toxic nature and high moisture content. industrial

Major Sources of Industrial Sludge

Industrial sludge originates from a variety of sectors :

- Chemical and Petrochemical Plants: These facilities produce sludge rich in hydrocarbons and heavy metals.

- Textile and Dye Industries: These operations generate sludge with vibrant colors, often containing azo dyes and salts.

- Metal Finishing and Electroplating Units: These processes yield sludge laden with metals like zinc, copper, or chromium.

- Paper and Pulp Mills: These mills create sludge primarily composed of organic matter and cellulose fibers.

- Food Processing Industries: These businesses generate biodegradable sludge with a high organic content.

Chemical and Biological Composition of Sludge

Industrial sludge is a complex mixture that typically contains:

- Organic Matter (30–70%)

- Heavy Metals (such as Lead, Cadmium, Mercury)

- Pathogenic Microorganisms

- Synthetic Chemicals and Oils The specific composition varies greatly depending on the industrial processes involved, which makes developing standardized treatment methods a challenge.

Types of Industrial Sludge

Organic Sludge

This category of sludge primarily originates from the food, paper, and textile industries. It contains biodegradable compounds and can often be treated biologically or transformed into biofertilizer after stabilization.

Inorganic Sludge

Inorganic sludge, commonly encountered in metallurgical and chemical industries, is composed of mineral particles, metals, and other inorganic contaminants. These types of sludge require thermal or chemical treatments to ensure they are safe.

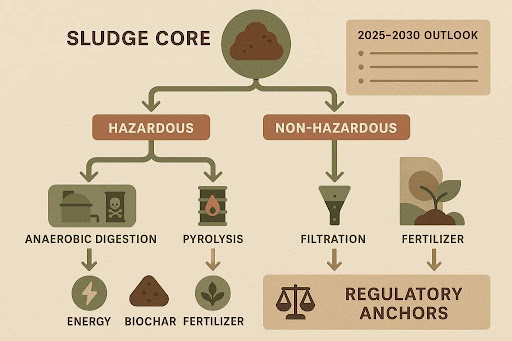

Hazardous vs. Non-Hazardous Sludge

- Hazardous Sludge: This sludge contains toxic elements, such as lead, arsenic, and chromium, that have the potential to contaminate soil and water.

- Non-Hazardous Sludge: This type is generally biodegradable and less toxic, making it suitable for composting or land application after appropriate treatment.

The Environmental Consequences of Improper Sludge Disposal

Soil and Water Contamination

Disposing of untreated sludge can lead to heavy metals leaching into soil and groundwater, posing significant health risks. Contaminated water sources can result in bioaccumulation in crops and aquatic life.

Air Pollution and Odor Issues

As organic sludge decomposes, it releases unpleasant odors and greenhouse gases like methane and hydrogen sulfide. Improper incineration can release harmful dioxins and furans into the atmosphere.

Long-Term Effects on Ecosystems

Persistent pollutants found in sludge can disrupt soil microbial communities, reduce crop yields, and damage aquatic habitats, leading to long-term ecological imbalances—sustainable waste management.

Industrial Sludge Management Techniques

Thickening and Dewatering Methods

Mechanical processes such as centrifugation, filtration, and belt presses are employed to remove water content. This effectively reduces the sludge volume, thereby lowering transportation costs.

Chemical Stabilization and Conditioning

Materials like lime, ferric chloride, or polymers are added to neutralize pH levels, reduce pathogen presence, and improve the sludge’s ability to be dewatered.

Thermal and Biological Treatment Options

Thermal drying, composting, and anaerobic digestion are methods used to convert sludge into energy or soil conditioners, making the overall process more sustainable.

Advanced Technologies in Sludge Treatment

Anaerobic Digestion and Biogas Production

One of the most effective ways to manage organic industrial sludge is through anaerobic digestion. This process involves microorganisms breaking down organic matter in the absence of oxygen. Not only does this reduce the sludge volume, but it also generates biogas, a valuable renewable energy source. Many forward-thinking industries are now investing in anaerobic digesters to achieve both energy recovery and waste reduction simultaneously. For example, food and beverage manufacturers commonly use this method to convert sludge with high organic content into electricity and heat for their own operational needs.

Pyrolysis and Gasification

For sludge with a substantial amount of organic solids, pyrolysis and gasification are emerging as environmentally sound thermal treatment options. waste gasification

- Pyrolysis breaks down sludge at high temperatures without oxygen, producing bio-oil, syngas, and char.

- Gasification converts sludge into a combustible gas mixture that can be used to power turbines or generate hydrogen fuel. These advanced methods significantly decrease waste volume while recovering valuable resources, aligning perfectly with circular economy principles.

Membrane Filtration Systems

Technologies like ultrafiltration, nanofiltration, and reverse osmosis are utilized to separate solids and liquids at a molecular level. Modern membrane bioreactors (MBRs) not only enhance wastewater treatment effectiveness but also substantially minimize sludge production, making them a preferred choice for industries prioritizing sustainability and regulatory compliance.

Sustainable Disposal and Reuse of Industrial Sludge

Land Application and Soil Amendment

When industrial sludge is properly treated and stabilized, its nutrient content (nitrogen, phosphorus, organic carbon) allows it to be repurposed as a soil conditioner. However, rigorous monitoring for heavy metals and pathogens is crucial to prevent contamination.

Cement and Brick Manufacturing

Dried industrial sludge can be incorporated as an alternative raw material or fuel in cement kilns and brick manufacturing. Its mineral-rich composition, including silica and calcium, makes it an excellent additive that enhances the strength of construction materials while reducing the need for virgin resource extraction.

Metal Recovery from Sludge Ash

Ash derived from industrial sludge, particularly from metal-finishing or plating operations, is often rich in valuable metals like zinc, copper, and nickel. Employing hydrometallurgical and bioleaching techniques allows for the extraction of these metals, thereby decreasing reliance on mining and minimizing environmental risks.

Global Regulations and Standards for Sludge Management

EPA and EU Sludge Directives

In the United States, the Environmental Protection Agency (EPA) enforces 40 CFR Part 503, a regulation that governs the use and disposal of both sewage and industrial sludge. Concurrently, the European Union’s Sludge Directive (86/278/EEC) specifically addresses agricultural reuse and the control of pollutants. Both regulatory frameworks emphasize the importance of stabilization, pathogen reduction, and traceability in sludge management practices.

Indian CPCB Guidelines and Challenges

India’s Central Pollution Control Board (CPCB) mandates that industries adhere to stringent sludge handling and disposal norms under the Hazardous Waste Management Rules (2016). Nevertheless, compliance remains inconsistent, particularly among small-scale industries, largely due to high treatment costs and limited infrastructure.

Corporate Compliance and Reporting Requirements

Leading multinational corporations are increasingly publishing ESG (Environmental, Social, and Governance) reports that detail their waste management strategies, including specific targets for sludge reduction. Transparent sludge management practices are rapidly becoming a critical factor in global sustainability assessments.

Case Studies: Successful Industrial Sludge Management Programs

Japan’s Waste-to-Energy Initiatives

Japan is a global leader in sludge-to-energy conversion, utilizing advanced incineration and gasification technologies. Major cities like Tokyo successfully convert over 60% of their sludge into energy and construction materials, significantly reducing their reliance on landfills. Waste-to-energy is an essential aspect of this transition.

Germany’s Circular Economy Model

Germany’s robust environmental legislation has fostered a comprehensive circular economy approach. In this model, sludge is either composted, digested, or thermally treated for energy recovery. Currently, over 90% of sludge in Germany is reused sustainably.

Emerging Solutions in Southeast Asia

Nations such as Singapore and Thailand are making substantial investments in solar drying and biogas facilities, effectively transforming industrial waste challenges into valuable renewable energy opportunities.

The Role of Innovation and Research in Reducing Sludge Generation

Cleaner Production Techniques

Industries are progressively adopting cleaner production methods. These include process redesign, optimized chemical usage, and waste minimization strategies aimed at reducing sludge at its source. For instance, transitioning to closed-loop water systems effectively minimizes both sludge output and wastewater discharge.

Industrial Water Recycling Systems

Advanced zero liquid discharge (ZLD) systems are capable of recovering nearly all wastewater, leaving behind only a minimal amount of concentrated sludge. These systems are becoming increasingly mandated in numerous industrial zones worldwide.

Bioengineering and Green Chemistry Approaches

Research is actively exploring bioengineered microorganisms and environmentally friendly coagulants to enhance sludge digestibility and reduce its toxicity. Green chemistry principles guide the replacement of hazardous reagents with biodegradable alternatives, thereby minimizing sludge toxicity at the molecular level.

The Future of Industrial Sludge Treatment (2025–2030 Outlook)

AI and IoT in Sludge Monitoring

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is ushering in a new era for sludge management. Smart sensors and predictive analytics enable real-time monitoring of sludge quality and treatment process efficiency, leading to optimized operations and reduced costs.

Carbon-Neutral Treatment Plants

Future sludge management systems are being designed to achieve carbon neutrality. This is accomplished by integrating biogas recovery, solar drying, and carbon dioxide sequestration technologies. Such advanced facilities are projected to generate more energy than they consume.

The Shift Toward Circular Economy Models

By 2030, industrial sludge will no longer be categorized as mere waste but recognized as a valuable resource stream. Strategies focused on materials recovery, renewable energy production, and resource reuse will become the dominant approaches in global sludge management.

Conclusion: Toward a Sustainable and Circular Future for Industrial Sludge

Industrial sludge presents both a significant challenge and a considerable opportunity. When left untreated, it poses a threat to ecosystems and public health. However, through the application of innovative technologies, robust regulations, and the principles of a circular economy, sludge can be transformed into a valuable resource—powering industries, enabling metal reclamation, and restoring environmental equilibrium.

The transition to sustainable sludge management necessitates strong collaboration among industries, governmental bodies, and research institutions. By 2030, industries that actively embrace innovation and transparency in their sludge management practices will spearhead the shift towards a more sustainable, cleaner, and circular industrial future.

🔗 External Link: Explore global sludge management initiatives further on the EPA Sludge Management Portal.