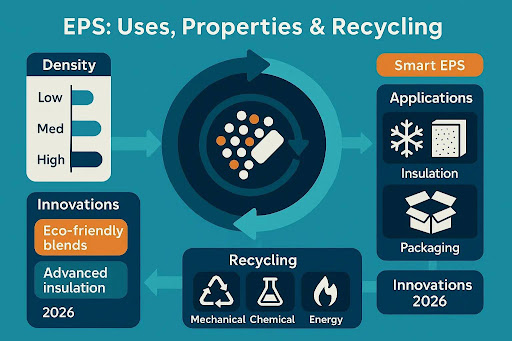

Expanded Polystyrene (EPS) is a lightweight, rigid closed‑cell foam used across construction, packaging, and consumer goods because it insulates well and is easy to shape. This guide explains what EPS is, how it’s made, its key physical and thermal properties, common uses, and the recycling pathways and innovations that are helping the industry reduce waste. You’ll find practical detail on composition, performance differences by density, and the recycling technologies—mechanical, chemical, and thermal—that support a more circular approach to EPS material use. EPS foam regulations

What is Expanded Polystyrene Foam and How is it Made?

Expanded Polystyrene (EPS) is produced from polystyrene beads that are expanded with a blowing agent and fused to form a rigid foam. The process yields a stable, low‑weight material with strong thermal insulation and good moisture resistance. Because EPS can be molded into boards, blocks, or custom shapes, it’s widely adopted for insulation panels, protective packaging, and a variety of consumer products. Manufacture centers on heating and expanding the beads, then shaping and fusing them to achieve the final geometry and performance.

What are the key components and composition of EPS foam?

EPS is built mainly from polystyrene, a synthetic aromatic hydrocarbon polymer. Typical components are:

- Polystyrene Beads: The base raw material that forms the foam’s cellular matrix.

- Blowing Agents: Substances (historically, pentane) used to expand beads during pre‑expansion and molding, creating the foam’s closed cells.

- Additives: Formulation extras added to improve fire performance, UV stability, color, or other targeted properties.

That combination gives EPS a favorable balance of low weight and mechanical integrity, making it appropriate for a broad set of uses where insulation and formability matter.

How does the EPS manufacturing process work using polystyrene beads?

Manufacture of EPS typically follows a few defined stages:

- Pre-Expansion: Steam and a blowing agent heat the beads, causing them to expand into a cellular foam.

- Aging: Expanded beads cool and stabilize, allowing trapped gases to equilibrate and improving handling.

- Molding: Stabilized beads are placed in molds and reheated so they fuse into a continuous, shaped product.

- Cooling and Finishing: Molded pieces are cooled, trimmed, and sized to final specifications.

These steps produce versatile EPS forms—from rigid insulation boards to precision molded packaging—tailored to the application’s dimensional and performance needs.

What are the Physical and Thermal Properties of EPS Foam?

EPS offers a set of physical and thermal attributes that make it an effective and economical insulator. It is lightweight, moisture-resistant due to its closed-cell structure, and delivers predictable thermal performance across many construction and packaging applications.

How does foam density affect the performance of EPS insulation?

Density is one of the main levers that determine EPS performance. In general:

- Low-Density EPS: Lighter and less costly; suitable for basic packaging and non‑structural insulation where extreme thermal resistance isn’t required.

- Medium-Density EPS: A practical middle ground balancing cost, insulation, and durability for many building and packaging uses.

- High-Density EPS: Delivers stronger thermal resistance and better structural properties for demanding applications such as heavy‑load insulation or specialized packaging.

Selecting the right density is essential to meet thermal, mechanical, and economic targets for any project.

What makes EPS foam effective for thermal insulation applications?

EPS performs well as an insulator for three main reasons:

- Low Thermal Conductivity: Typical EPS thermal conductivity sits around 0.032 to 0.038 W/m·K, giving reliable heat‑flow resistance.

- Moisture Resistance: The closed‑cell structure limits water absorption, helping the material retain insulating performance over time.

- Lightweight: Easier handling and installation reduce labor and transport costs on site.

Those combined traits explain why EPS is widely specified in residential and commercial building envelopes as well as in temperature‑sensitive packaging.

How is EPS Foam Used in Insulation and Packaging Applications?

EPS finds use across insulation and protective packaging because it can be formed to exact shapes, offers predictable thermal performance, and remains cost-competitive. Its versatility makes it useful to a broad set of industries.

What are the benefits of EPS foam sheets and blocks in construction insulation?

EPS sheets and blocks offer several practical benefits for construction:

- Cost-Effectiveness: EPS is generally more affordable than many alternative insulation materials, helping lower project costs.

- Thermal Performance: Good R‑value per thickness helps reduce heating and cooling loads and energy bills.

- Durability: EPS resists moisture and maintains shape and performance over long service lives.

Those advantages make EPS a go‑to option for builders focused on energy efficiency and predictable lifecycle performance.

Research supports the broad utility of EPS as an effective, economical insulator in building design.

EPS Insulation Benefits in Building Construction This article establishes the feasibility and benefit of EPS as an insulator that satisfies all insulation requirements in the building design process, including thermal performance, moisture resistance, durability, and cost-effectiveness, leading to energy savings, low maintenance, fast, and economic construction. Application of expanded polystyrene (EPS) in buildings and constructions: A review, NH Ramli Sulong, 2019

How does EPS molded packaging protect products during shipping?

Molded EPS is designed to protect items in transit by combining impact protection with low weight and tailored fit:

- Shock Absorption: The foam’s cellular structure dissipates impact energy and cushions fragile goods.

- Lightweight Design: Low mass cuts shipping costs while keeping protection high.

- Customizability: Molding lets EPS conform exactly to product shapes for a secure fit and improved damage prevention.

These features make molded EPS a common choice for electronics, appliances, food containers, and other items that need reliable transport protection.

What are the Environmental Impacts and Recycling Processes for EPS?

EPS brings clear performance benefits, but it also presents environmental challenges because it’s not biodegradable and can be bulky in the waste stream. Understanding recycling options and lifecycle impacts is essential to using EPS more sustainably.

Is EPS foam recyclable, and what are the common recycling methods?

EPS is recyclable, and the industry uses several core methods:

- Mechanical Recycling: EPS is crushed or ground and then reprocessed into new parts or pellets through remelting and reforming.

- Chemical Recycling: Depolymerization breaks EPS back into styrene monomers that can be purified and repolymerized into new polystyrene products.

- Energy Recovery: In controlled facilities, EPS can be used for energy recovery, though emissions and resource trade‑offs make this a less preferred route when recovery and recycling are available.

Chemical recycling in particular offers a promising route to close the loop by returning EPS waste to feedstock for new material production.

Chemical Recycling of EPS for the Circular Economy Chemical recycling of plastic waste offers a perspective aligned with circular economy principles, enabling the recovery of valuable monomers or other chemicals from waste polymers. This study focuses on the chemical recycling of expanded polystyrene (EPS) waste through depolymerization to produce recycled styrene monomer, which can then be used to synthesize new polystyrene. Circular economy of expanded polystyrene waste: Techno-economic and life cycle assessments of chemical recycling processes, EI Fitriasari, 2025

Where collection and processing exist, recycling EPS reduces landfill burden and supports circular‑economy goals.

Additional studies outline the range of recycling pathways and potential reuse applications for recycled EPS.

EPS Waste Recycling Methods & Applications Expanded polystyrene (EPS) is used in electrical/electronic appliances as a shock absorber and constitutes a reasonable percentage of the entire plastic waste. There are three methods of recycling expanded polystyrene: mechanical, chemical, and thermal recycling; each of the above methods gives rise to different products that are used in different applications. Expanded polystyrene is used as a binder in emulsion paint as a replacement for conventional binders; as a component of asphalt used in road construction; as a component of wood plastic composites; and as a blend with silica and in concrete to produce lightweight construction material. This article studied the various applications of recycled polystyrene waste from mechanical, chemical, and thermal methods of waste recycling. A mini-review on expanded polystyrene waste recycling and its applications, SC Ugwu, 2023

What innovations exist in EPS recycling and sustainability efforts?

Recent work focuses on speeding up recycling, cutting environmental impacts, and broadening end‑markets for recycled EPS. Notable trends include:

- Closed-Loop Recycling Technologies: Systems designed to recycle EPS back into like‑for‑like products, reducing reliance on virgin feedstock.

- Biodegradable Alternatives: Research into bio‑based foams and compostable formulations aims to offer lower‑impact options for select uses.

- Enhanced Collection Systems: Better sorting, collection, and aggregation methods are increasing recovery rates for EPS waste.

Together, these advances help lower the lifecycle footprint of EPS and expand practical recycling options.

What are the Latest Innovations and Future Trends in EPS Foam Technology?

The EPS sector continues to evolve with product and process innovations that boost performance and sustainability.

How are closed-loop recycling technologies advancing EPS sustainability?

Closed‑loop recycling is enabling manufacturers to convert post‑consumer and post‑industrial EPS back into new EPS products. Benefits include:

- Resource Efficiency: Less virgin material is required when recycled material is reintroduced to production.

- Cost Savings: Recycling can lower raw material costs and reduce exposure to feedstock price swings.

- Sustainability: Closed‑loop models support circular economy goals by keeping material in productive use.

As these systems scale, they will play a central role in reducing the environmental impact of EPS.

What new EPS foam products and applications are emerging in 2026?

New EPS developments are focused on smarter performance and lower environmental impact. Examples include:

- Smart EPS: Embedded sensors for real‑time monitoring of temperature and humidity in sensitive shipments.

- Eco-Friendly Blends: EPS formulations that include biodegradable or bio‑based additives to reduce lifecycle impacts where feasible.

- Advanced Insulation Solutions: Higher‑performance EPS products engineered to meet stricter energy‑efficiency standards in building construction.

These trends show EPS adapting to market demands for smarter, greener, and higher‑performing materials while retaining the core benefits that make it useful today.